Why choose stainless steel pneumatic ball valves?

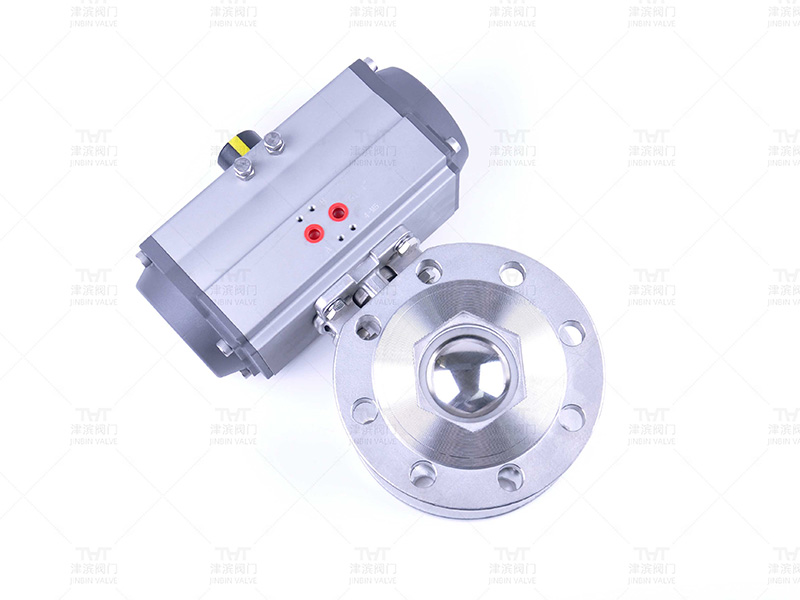

In the selection of valves for various projects, stainless steel pneumatic ball valve is often listed as one of the important valves. Because this flange type ball valve has its unique advantages in use.

A. Corrosion resistance is suitable for many harsh environments. The 304 ball valve body is made of stainless steel (such as CF8, CF8M), which can resist corrosion from water, weak acids and alkalis, salt spray, etc. It is suitable for the transportation of slightly corrosive media in the chemical industry, and also meets the anti-rust requirements of water treatment and municipal water supply. Moreover, the CF8M material (containing molybdenum) can be used to deal with more corrosive scenarios such as seawater and weak acids, avoiding valve body leakage or shortened service life caused by medium erosion.

B. Pneumatic drive efficiently ADAPTS to automation. Relying on compressed air to drive the ball valve core to rotate, the on-off response speed is fast (usually 0.5 to 3 seconds), far exceeding that of manual valves. It can be combined with components such as solenoid valves and positioners to achieve remote control or linkage with PLC systems, eliminating the need for on-site manual operation. It is particularly suitable for high-risk (such as toxic media), high-altitude or dense pipeline scenarios, significantly enhancing operational efficiency and safety.

C. Structural advantages reduce operational losses. It adopts a "spherical rotation shut-off" design. When fully open, the flow channel is unobstructed, with a flow resistance coefficient of only 0.1-0.3, which is much lower than that of gate valves and globe valves, and can reduce the energy consumption for medium transportation. Meanwhile, the soft seal (such as PTFE) is closely attached to the stainless steel ball, and the leakage can reach ANSI Class VI level (almost no leakage), avoiding medium waste or contamination.

D. It has strong adaptability to working conditions and is easy to maintain. The stainless steel ball valve body has a wide temperature resistance range (-200℃ to 400℃), which can cover scenarios such as low-temperature liquid nitrogen and medium-temperature steam. Compact in structure and easy to disassemble, daily maintenance only requires checking the seals or cleaning the valve core, without complex disassembly. Its service life can reach 8 to 10 years, with low comprehensive operation and maintenance costs. It is widely applicable in fields such as chemical engineering, water treatment, food and medicine, and energy.

Jinbin Valves has been deeply engaged in the valve field for 20 years. ISO certification has solidified the foundation of quality, and it has broken through and innovated with multiple patented technologies. From butterfly valves to gate valves, with large-diameter specifications ranging from DN40 to DN3000, it caters to the demands of multiple industries such as water conservancy, petrochemicals, and power. If you have any valve customization or purchasing needs, please send a message below and you will receive a reply within 24 hours!