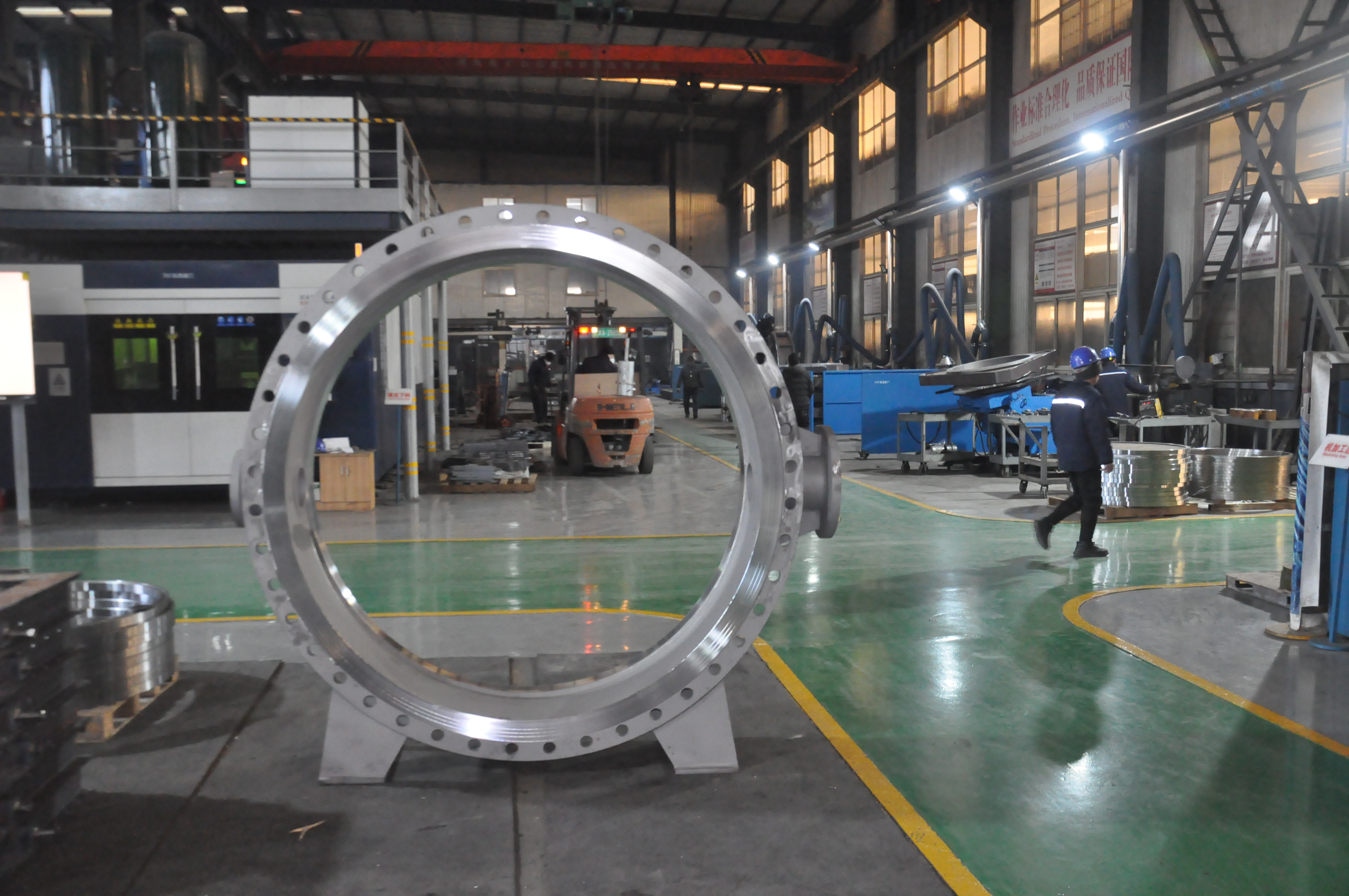

HYDRAULIC BUTTERFLY VALVE FOR SEA WATER DN1800 PN10

- THT

- TIANJIN

- 45DAYS

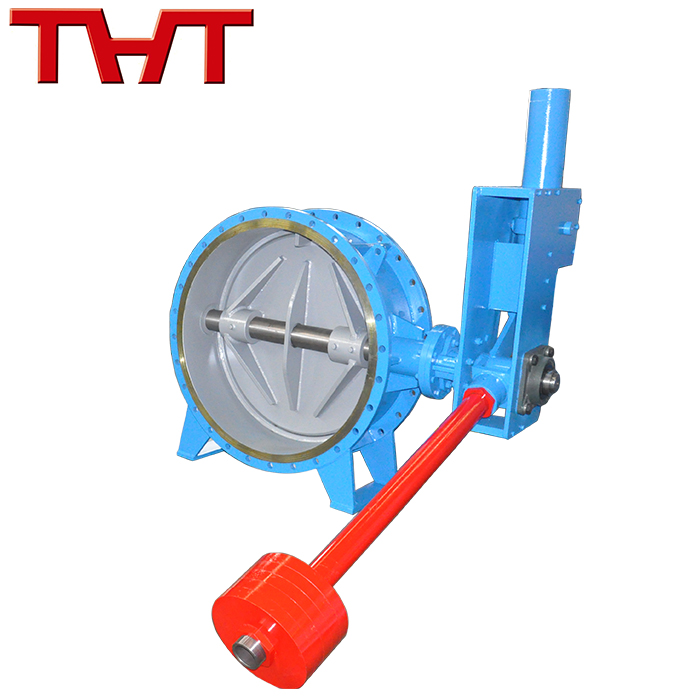

The hydraulic butterfly valve DN1800 PN10 is a high-performance, flanged butterfly valve engineered for critical, large-diameter seawater flow control in marine and offshore environments. Designed to DN1800 (1800mm nominal diameter) and pressure rated to PN10, this valve combines a robust, corrosion-resistant body with a powerful, fail-safe hydraulic actuation system. It is the definitive solution for seawater intake and discharge, cooling water systems, desalination plants, and offshore water management where reliability, longevity, and minimal maintenance are paramount.

Key Features & Benefits

Superior Corrosion Resistance for Seawater:

Body & Disc: Constructed from Duplex Stainless Steel (UNS S32205/S31803) or Super Duplex Stainless Steel (UNS S32750) upon request. This provides exceptional resistance to chloride-induced pitting, crevice corrosion, and stress corrosion cracking, far surpassing standard 316 stainless steel.

Seat: A resilient, ECC (Erosion-Corrosion Resistant) seat with a proprietary elastomer compound (e.g., EPDM or HNBR) formulated for prolonged exposure to abrasive saline water, ensuring a bubble-tight seal.

Stem: A one-piece, through-stem design made from high-strength Duplex stainless steel, eliminating weak points and ensuring reliable torque transmission.

Powerful & Reliable Hydraulic Actuation:

Double-Acting or Spring-Return Hydraulic Actuator: Provides high torque output for smooth, positive operation of the large DN1800 disc against differential pressure. The spring-return (fail-safe) model automatically moves the valve to a predetermined safe position (open or closed) upon loss of hydraulic pressure or emergency shutdown.

Integrated Hydraulic Power Unit (HPU): Supplied as a complete, skid-mounted system for plug-and-play installation. The HPU includes filters, accumulators for emergency cycles, and precision control valves for adjustable operation speed.

Precision Control: Allows for precise modulating control or simple on/off function, ideal for flow regulation in large seawater systems.

Robust Mechanical Design:

Fully Lugged Body Design: Allows easy installation between ANSI/PN flanges without needing dedicated nuts for the valve side, facilitating installation and maintenance. Bolt holes are drilled to ISO 5210 mounting standards.

Eccentric Disc Design (Triple or Double Offset): The disc is offset from the seat and stem centerline, enabling a cam-action operation. This eliminates constant seal wear, provides a scraping action for self-cleaning, and ensures a zero-leakage shut-off.

Continuous, Adjustable Seat: The seat design allows for easy in-line adjustment or replacement in many cases, extending service life.

Operational Security & Longevity:

Heavy-Duty Bearings: Self-lubricating, corrosion-resistant bearings support the stem, minimizing friction and ensuring smooth operation over thousands of cycles.

Corrosion Protection: All external surfaces receive a high-build epoxy coating (e.g., 300+ microns) compatible with seawater and UV exposure for additional protection.

Multiple Position Indication: Local visual position indicator (VI), mechanical limit switches, and optional potentiometers for remote feedback to SCADA/DCS systems.

Technical Specifications

| Parameter | Specification |

|---|---|

| Valve Type | High-Performance, Triple/Double Eccentric Butterfly Valve |

| Size (Nominal) | DN1800 (NPS 72) |

| Pressure Rating | PN10 (10 bar, ~145 psi) |

| Test Pressure | Shell Test: 1.5 x PN (15 bar); Seat Test: 1.1 x PN (11 bar) |

| Body Material | Duplex Stainless Steel (UNS S32205) – Super Duplex Optional |

| Disc Material | Duplex Stainless Steel, Clad with Corrosion-Resistant Alloy if specified |

| Stem Material | High-Strength Duplex Stainless Steel (One-Piece Design) |

| Seat Material | ECC Elastomer (EPDM or HNBR), Fire-Safe (API 607) version available |

| Actuator Type | Hydraulic, Double-Acting or Spring-Return (Fail-Safe) |

| Actuation Torque | As per calculated requirement for DN1800 PN10 service (supplied with 30% margin). |

| Flange Standards | EN 1092-2 (PN10/16) or ASME B16.5 Class 150 (Drilling to customer specification) |

| Face-to-Face | Compliant with EN 558 / API 609 |

| Operating Temp. | -20°C to +80°C (Seat dependent) |

| Flow Characteristic | Near-equal percentage (modulating) or On/Off |

Typical Applications

Seawater Intake & Outfall Systems for Power Plants

Desalination Plant Feed and Brine Discharge Lines

Offshore Platform Seawater Injection & Cooling Systems

Shipyard and Dry Dock Water Supply

Large Marine Cooling Water Circuits

Coastal Flood Control & Stormwater Management

Why Choose the HYDRAULIC BUTTERFLY VALVE FOR SEA WATER DN1800 PN10?

Engineered for the Environment: Every material is selected to combat the aggressive nature of seawater.

Uncompromising Reliability: Designed for zero leakage, high cycle life, and minimal total cost of ownership.

Complete Package: Supplied as a fully tested, valve-actuator-HPU assembly, ready for integration.

Global Standards: Manufactured in accordance with ISO, EN, API, and other major international standards.