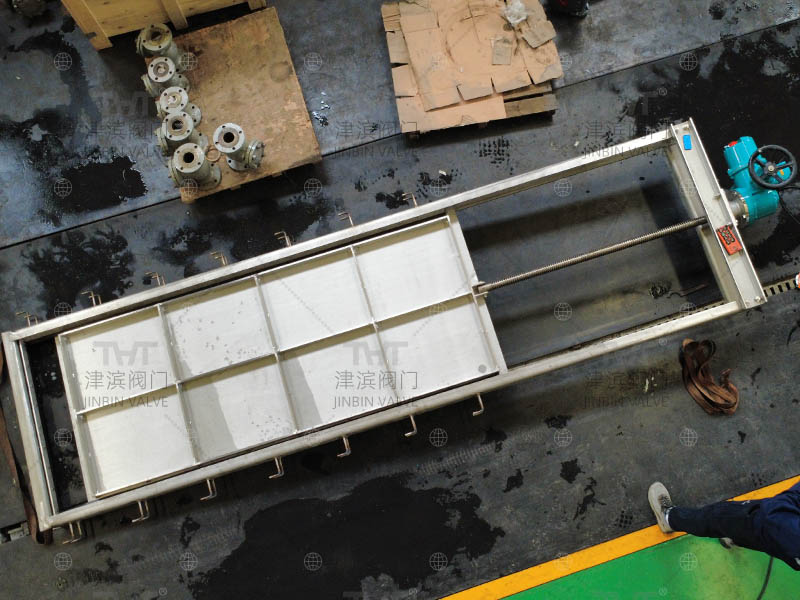

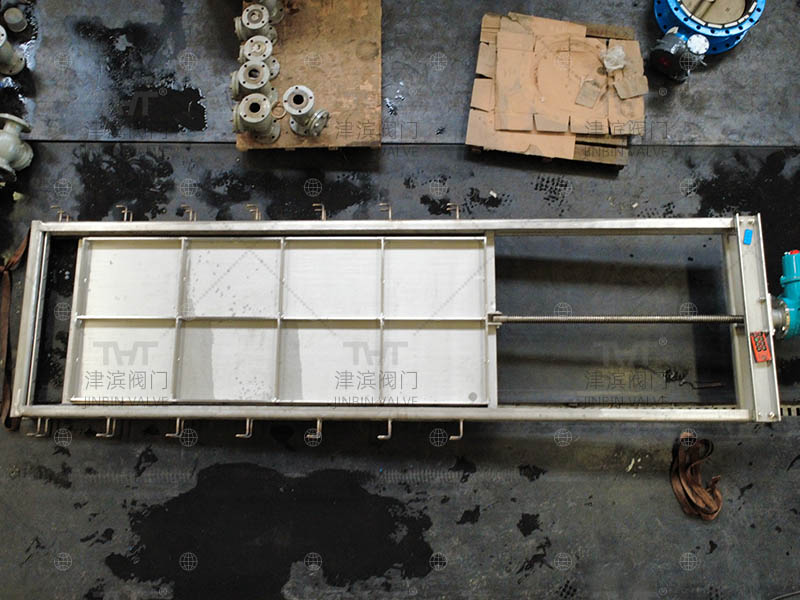

Factory commissioning of 2-meter channel penstock gate

In the Jinbin workshop, a 2-meter stainless steel channel mounted penstock gate valve customized by a customer is undergoing electrical installation and debugging, and workers are checking the opening and closing of the gate plate. The 2-meter stainless steel channel penstock gate (with the mainstream material being 304/316L stainless steel) is a core control device designed for high-flow channel water conveyance scenarios. With its material properties and structural optimization, it holds an important position in fields such as water conservancy, municipal works, and industry.

Its core features are concentrated in three dimensions: structure, sealing and operation: It adopts an integrated formed sluice gate plate and door frame, which is compact and highly rigid, suitable for the flow control requirements of 2-meter diameter channels, and has no redundant design. The sealing system adopts rubber soft seals or metal hard seals, combined with precise processing techniques, ensuring a high degree of fit between the gate plate and the door frame, achieving a zero-leakage sealing effect. The operation mode supports manual hoists and electric hoists (with an optional remote control module), adapting to convenient operation under different working conditions. The electric model has a fast response speed, while the manual model has a low maintenance cost.

Stainless steel penstock valve has extremely strong corrosion resistance and wear resistance. It can resist the erosion of complex media such as acidic and alkaline sewage and sandy water flow. Its service life is 3 to 5 times longer than that of ordinary carbon steel gate valve. The large diameter meets the demand for high-flow water transmission, with a smooth flow cross-section and low hydraulic loss, ensuring the water transmission efficiency of the channel. The structural design takes into account both installation and maintenance. It is lightweight and easy to disassemble and assemble. Maintenance can be completed without complex tools, reducing operation and maintenance costs. It has excellent environmental protection performance. Made of stainless steel, it causes no secondary pollution and meets environmental protection standards for drinking water and sewage treatment. Moreover, it has stable high and low temperature resistance and is suitable for extreme working conditions ranging from -20 ℃ to 80℃.

The application scenarios cover the core working conditions of multiple industries: In water conservancy projects, it is used for water level regulation and flow control in river management, reservoir spillways, and farmland irrigation channels, especially suitable for the main channels of large-scale irrigation districts and cross-regional water diversion projects. In the field of municipal water supply and drainage, it is widely applied in the intake and drainage channels of sewage treatment plants, the interception of rainwater networks, and the raw water transportation channels of waterworks, and can precisely control the water flow switch and flow rate. In the industrial field, it is applicable to the circulating water channels and wastewater treatment channels in the chemical, power and metallurgical industries, resisting the corrosion of industrial wastewater and ensuring the stability of production water supply.