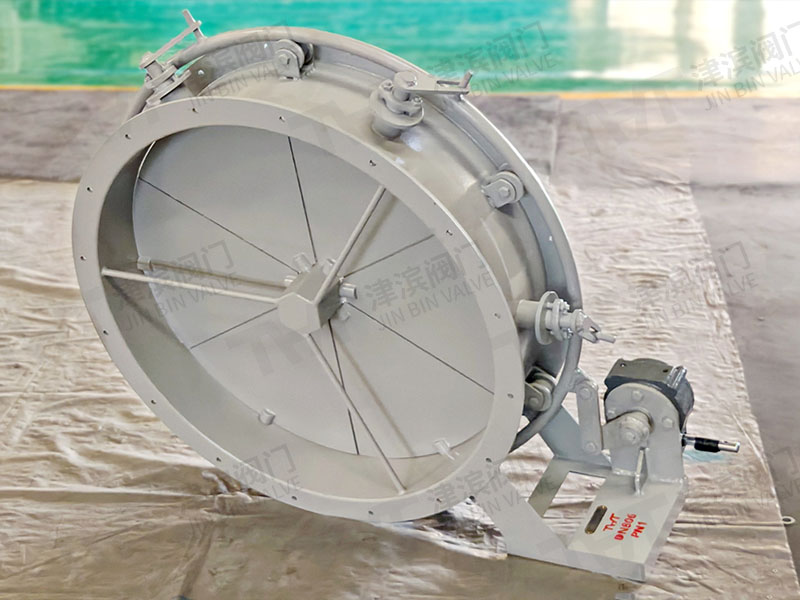

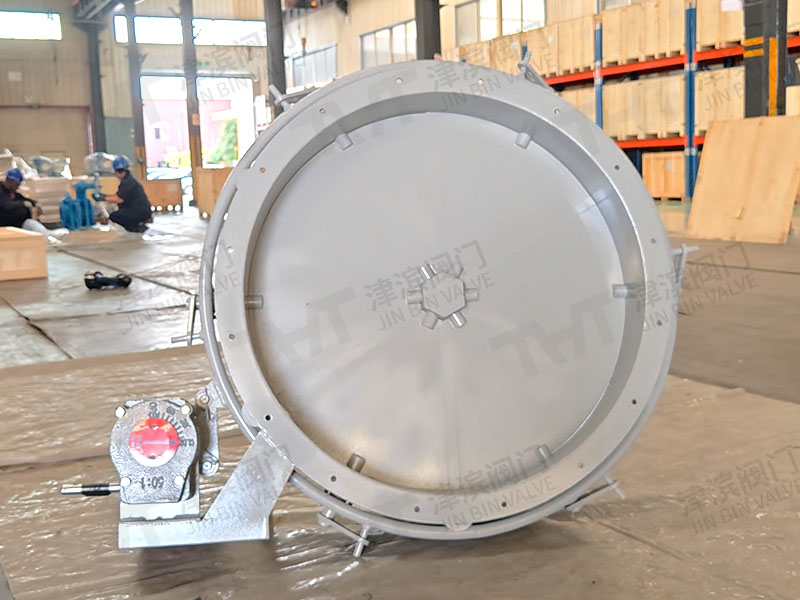

The DN806 carbon steel air damper valve has been dispatched

In the Jinbin workshop, several custom-made gas damper valves for customers have begun packaging and are ready for shipment. The size varies from DN405/806/906, and it is made of carbon steel. The carbon steel air damper, with its characteristics of "high tolerance, strong sealing and low cost", perfectly meets the complex working conditions and cost control requirements of the mining and dust removal industries, and has become the mainstream choice for air duct control in these two scenarios.

From the perspective of working condition tolerance, in mining and dust removal systems, air valves need to withstand the long-term erosion of high-concentration dust, material impact and periodic pressure fluctuations. The carbon steel base material itself has high rigidity and hardness. After quenching, sandblasting or spraying wear-resistant coatings (such as epoxy resin, ceramic particles), its wear resistance can be further enhanced, effectively resisting the wear of hard particles such as ore dust and coal dust, and avoiding the sealing failure caused by the deformation of the valve plate and valve seat due to erosion. Meanwhile, the carbon steel structure has high strength and can withstand pressure fluctuations of ±5kPa within the air duct. In scenarios such as underground ventilation and dust removal systems in the mining industry, negative pressure exhaust is less likely to cause valve body deformation, ensuring long-term operational stability.

In terms of sealing performance and compatibility, the dust removal industry has strict requirements for the sealing performance of air ducts. Carbon steel air valves, through precisely processed sealing surfaces and combined with oil-resistant rubber or fluorine rubber sealing parts, can achieve efficient sealing and avoid reducing dust removal efficiency due to air leakage. Moreover, carbon steel can be formed by welding, making it easy to manufacture large-sized air valves (such as 2m×1.5m), which is suitable for the installation requirements of large ventilation tunnels and main air ducts of dust removal systems in the mining industry. In contrast, materials like stainless steel are prone to welding deformation during large-scale processing and have higher costs.

Economy and maintainability are the key advantages. The price of carbon steel raw materials is only one third of that of 304 stainless steel. Batch application can significantly reduce the initial investment in mining and dust removal projects. Meanwhile, the carbon steel damper valve has a simple structure and strong component universality (such as valve shafts and actuator interfaces). It is convenient to replace parts during later maintenance without the need for special tools. Even if there is slight rust on the surface, it can be repaired by sandblasting for rust removal and applying anti-corrosion paint. The operation and maintenance cost is much lower than that of alloy material flue gas dampers.

Jinbin Valve, a 20-year-old valve air damper valve manufacturer, produces and manufactures according to customer needs. If you have any related requirements, please contact us below and you will receive a reply within 24 hours!